Our Product

Gold Refining Plant

Gold Refining Plant

This gold refining plant is able to treat from 300 gram. up to 10 kg. of starting gold alloy. You are able to produce 99.99% pure gold (Au) in a single step within a production cycle that can last from 5 to 8 hours, from the preparation of the grains, to obtaining the pure ingot. The treatment takes place by dissolving the staring metal alloy through the use of the so-called “Aqua Regia” solution, an opportunely calibrated mixture of hydrochloric acid (HCl) and nitric acid (HNO3).

- Alloy Batch Charge 1 Kg to 100 Kg.

- Working Cycle Time In – 24 Hr 3 Batches

- Purity Can Be Obtained – Form 999.5 to 999.8-9/1000

- Electric Power Supply – 3Ph & 1Ph, Working Area – 10 ft. x 10 ft.

Machine advantages

- Very compact plant

- Easy handling

- Low operation costs

- No fumes

- No gold losses

- Automatic acid loading

- Very low maintenance system

Refining Using Aqua Regia Process

- Best suited for gold with an initial purity of at least 600/1000. Initial purities below this value can reduce the production capacity as well as increase process times.

- Recommended maximum silver content: 10-12%. The percentages above these values can reduce production capacity as well as increase process times.

- The gold should be either melted into fine grains – using a melting furnace and a grain tank – or very thin strips.

- Strips are ideal due to their large surface area and complete dissolution when emerged in the aqua regia solution.

- Grains, due to their irregular shape and size, are more difficult to dissolve and often leave leftovers in the reactor. On the other hand, they are quicker to produce than strips.

Machine Working Details and Specification

- Anti-acid polypropylene hood containing all the necessary equipment. Designed to recover acid losses.

- Electric heater with Digital Temperature Controls

- 3 Coil fume condenser

- Filter unit on wheels with a compressed air diaphragm pump (made in Italy) to transfer the solutions.

- Gold precipitation tank

- ADD tanks for HCl and HNO3. Acid transfer from the reactor air diaphragm pump (made in Italy)

- PPH tray stored.

- Compressed air diaphragm pump to transfer the solutions.

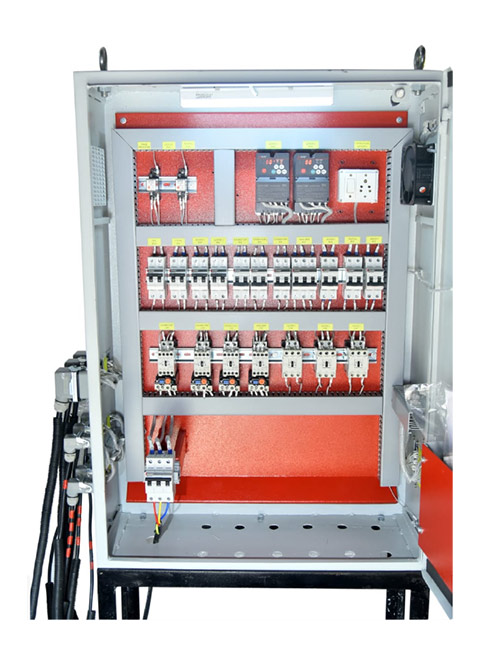

- Electric Panel – Control Panel.

- For safety purpose we provide separate MCB for each and every motor.

- Two drive for stirring motor.

- Temperature control with RPM meter.

- Safety emergency button and country type power supply.

Gold Refining Plant Technical Features

Gold Refining Plant Dissolution Reactor Unit

- Cylindrical Borosilicate Glass Reactor 50ltr Capacity with Discharge Valve.

- PTFE Stirring With Turbine Bled & 0.5 Hp Gear Motor.

- Electrical Heater For The Reactor With Complete Protected With Fibre Glass and Thermocouple RTD Temperature Sensor.

- Glass Condenser For 3 Coil Type for Recovery the Gold Chloride Fume Evaporated During The Gold Trap Bottle and Valve

- 2 Acid Charging System By AOD Pump ( Italy Make Pump ) & Charing P.P Pipe Line With Glass Charing Bottles

- PTFE Gasket And SS Nut bolts And Coating Flange and Fitting Parts

Gold Refining Plant Filtration Unit

- PP Spherical Filtering Unit

- The Used or Silver and other metal remove and only gold solution pass the precipitation rector

- Filter pump by AOD pump this pump for air operated (Italy make pump)

- The filter unit for Moveable type and easy used

- Top Acrylic cover for safety use and one nozzle for joint for scrubber unit

- Plant and Filter By PP Tray For Safety

Gold Refining Plant Precipitation Unit

- Cylindrical Borosilicate Glass Reactor 100ltr Capacity With Discharge Valve

- PTFE Stirring With Turbine Bled & 0.5 Hp Gear Motor

- 1 Gold Regent Charging System By AOD Pump (Italy Make Pump) & Charing P.P Pipe Line With Charging Bottles

- Reactor Safety Acrylic Bath And Seal Type Bath

- Reactor One Nozzle Joint to Scrubber Unit without fume operating and easy use

Gold Refining Plant Scrubber Unit

- This Scrubber Unit For three stag type unit

- Pre - Washing Scrubber Unit this use acid fume only washing With PP Tank and pump with glass NRV system

- Last Scrubber For the pp scrubber no acid fume for outside and easy charging nozzle for tank Two side opening Dumper valve and centre glass view type scrubber

- Scrubber Blower with Motor and pp cover Blower CFM – 2000

- Last Stage for carbon air filter for use no outside cling air pass

Electric control And Operating Panel

- Two Type Electric Penal – Operting / Control Penal

- For Safay Use we give saperate MCB for each and every motor.

- Two Drive For Stirring Motor

- Temp Contoral With RPM Meter

- Safaty Emerjency Button And Country Type Powe Supply

- All Motor and Pump connection are socket type so easy to connect with Plant and ready to use