Our Product

Automatic Gold Refining Machine

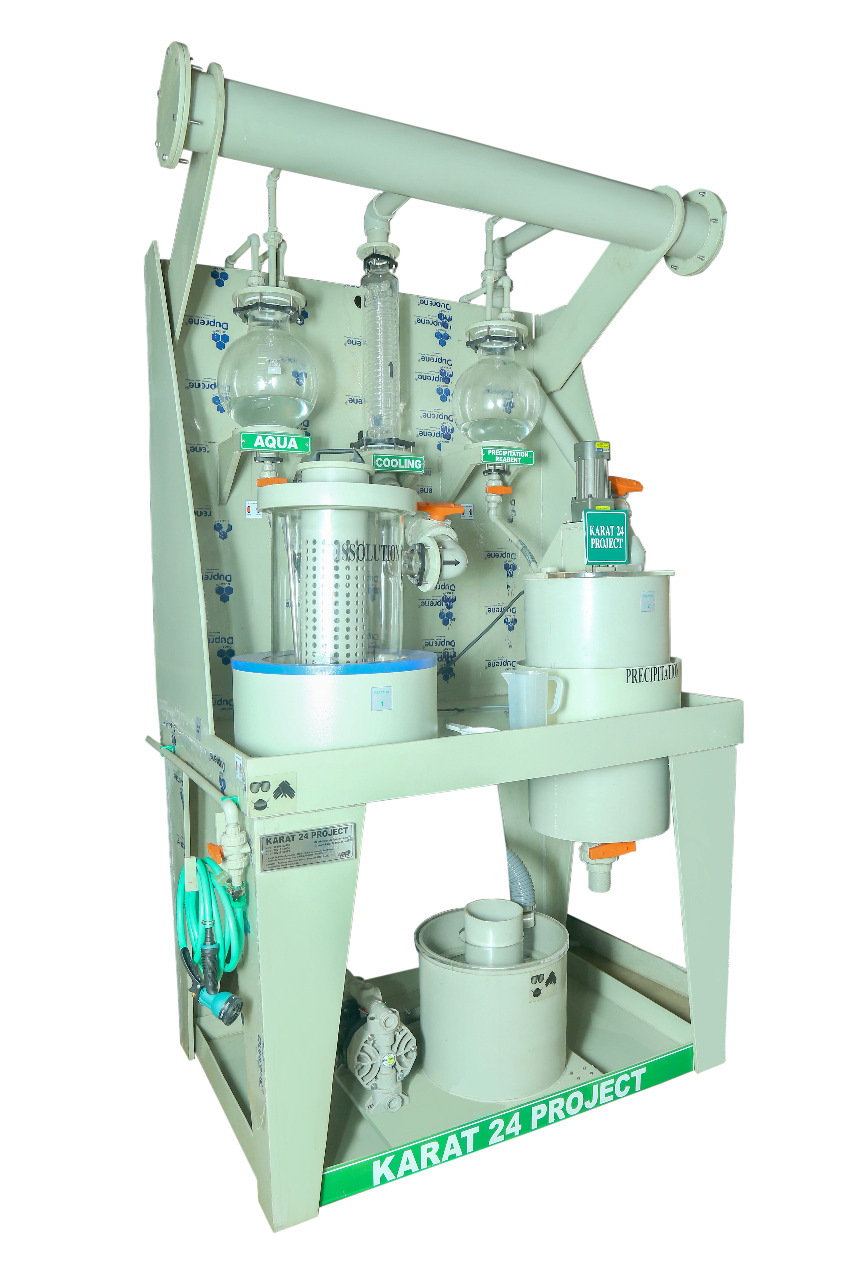

Automatic Gold Refining Machine

With the inclusion of advanced knowledge and innovative machines in all our processes, we are engaged in manufacturing and supplying a broad assortment of Automatic Gold Refining Machine. It is mainly used by goldsmith. It is a safe as well as reliable process of removing gold. It t is designed utilizing high grade material, procured from reliable sources of the industry as per the defined industry norms. Automatic Gold Refining Machine is widely known for its durability and quality.

- Alloy Batch Charge 1 Kg to 100 Kg.

- Working Cycle Time In – 24 Hr 3 Batches

- Purity Can Be Obtained – Form 999.5 to 999.8-9/1000

- Electric Power Supply – 3Ph

Machine advantages

- Very compact plant

- Easy handling

- Low operation costs

- No fumes

- No gold losses

- Automatic acid loading

- Very low maintenance system

Refining Using Aqua Regia Process

- Best suited for gold with an initial purity of at least 600/1000. Initial purities below this value can reduce the production capacity as well as increase process times.

- Recommended maximum silver content: 10-12%. The percentages above these values can reduce production capacity as well as increase process times.

- The gold should be either melted into fine grains – using a melting furnace and a grain tank – or very thin strips.

- Strips are ideal due to their large surface area and complete dissolution when emerged in the aqua regia solution.

- Grains, due to their irregular shape and size, are more difficult to dissolve and often leave leftovers in the reactor. On the other hand, they are quicker to produce than strips.

Machine Working Details and Specification

- Anti-acid polypropylene hood containing all the necessary equipment. Designed to recover acid losses.

- Electric heater with Digital Temperature Controls

- 3 Coil fume condenser

- Filter unit on wheels with a compressed air diaphragm pump (made in Italy) to transfer the solutions.

- Gold precipitation tank

- ADD tanks for HCl and HNO3. Acid transfer from the reactor air diaphragm pump (made in Italy)

- PPH tray stored.

- Compressed air diaphragm pump to transfer the solutions.

- Electric Panel – Control Panel.

- For safety purpose we provide separate MCB for each and every motor.

- Two drive for stirring motor.

- Temperature control with RPM meter.

- Safety emergency button and country type power supply.